ETD Electrical Engineering Division

EED | Code 560

Engineering Connections Between Worlds

The Electrical Engineering Division is composed of many branches all working in conjunction with one another in the research, development, and manufacturing of electronic instruments and technology to advance and benefit the scientific community at large.

Flight Data Systems & Radiation Effects Branch (561)

The Flight Data Systems & Radiation Effects Branch at NASA offers comprehensive services to support both in-house and out-of-house missions. The Flight Data Systems Group specializes in developing a wide range of hardware components (including Command and Data Handling (C&DH) subsystems and Ground Support Equipment (GSE), advancing new technologies, providing technical expertise in architecting, design, verification, and analysis (signal integrity, power integrity, etc.) and programmable logic devices such as Field Programmable Gate Arrays (FPGAs), and managing the development of complex technology. The Radiation Effects & Analysis Group operates the Radiation Effects Facility (REF), provides radiation hardness assurance for flight projects, characterizes space radiation environments, evaluates radiation effects on current and future EEEE part technologies, performs radiation effects testing, and provides shielding analysis for spacecraft and instrument hardware. With expertise in flight data systems and radiation effects engineering, the Branch plays a crucial role in advancing the state-of-the-art in analog and digital electronics and ensuring mission success for NASA projects.

Contact Code 561 Key Personnel

Parts, Packaging, & Assembly Technologies Branch (562)

The Parts, Packaging, and Assembly Technologies Branch provides comprehensive engineering services in the arena of Electrical/Electronics/Electromechanical/Electro-optical (EEEE) parts to meet the needs of flight instruments and spacecraft for Goddard Flight Projects as well as for external partners.The Parts, Packaging, and Assembly Technologies Branch provides comprehensive engineering services in the arena of Electrical, Electronics, Electromechanical, and Electro-optical (EEEE) parts to meet the performance, reliability, and programmatic needs of flight instruments and spacecraft for Goddard Flight Projects as well as for external partners from other NASA centers, Aerospace Companies and Universities. The branch consists of four main disciplines: Project Parts Engineering, Parts Analysis and Failure Analysis, Fiber Optics and Photonics, and Micro-Electronics Assembly Lab.

Contact Code 562 Key Personnel

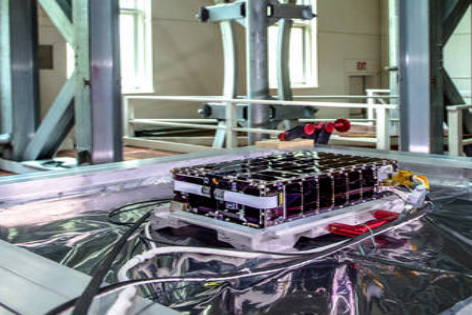

Power Systems Branch (563)

The Power Systems Branch provides the Center with expertise and capabilities in electrical power generation, conversion, management, distribution, and processing for space applications. Power systems engineering expertise is provided for all phases of science instrument, special payloads, and spacecraft flight projects, from conceptual design, through detailed design, development, test, launch, operations, and end-of-life disposal. Electrochemical discipline engineering expertise is provided to develop, deliver and operate flight batteries, and to advance energy storage technologies for longer life and higher energy density primary and secondary batteries, for payloads and spacecraft applications. Photovoltaic discipline engineering expertise is provided to design, develop and deliver flight solar cell arrays, and to advance solar-electric energy conversion technologies via higher efficiency solar cells for space flight applications.

Contact Code 563 Key Personnel

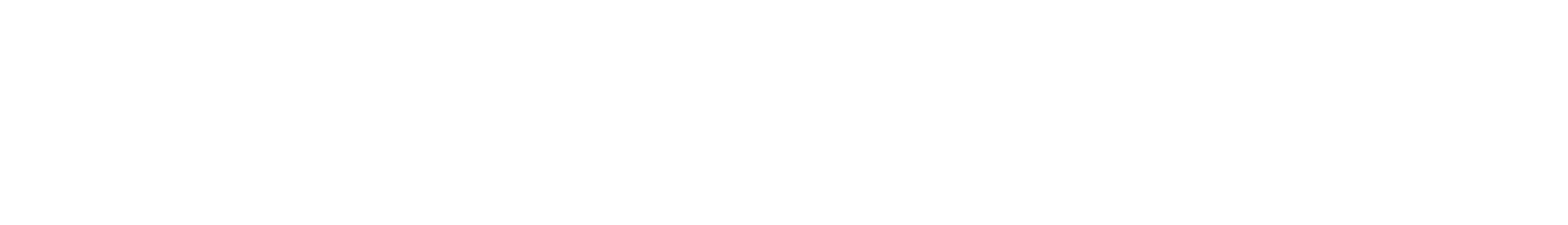

Instrument Electronics Development Branch (564)

The Instrument Electronics Development Branch provides leadership and expertise to design, develop, test, and deliver electronics systems for space flight science instruments including: front-end electronics, analog signal filtering and conditioning, temperature control electronics, analog-to-digital conversion, digital signal processing, and science data processing. In addition, the Branch develops analog and digital electronics to control various instrument sensors and actuators. The Branch provides expert personnel, utilizing specialized tools and laboratories, for the design, analysis, and test of advanced microelectronics devices such as mixed-signal application specific integrated circuits (ASICs) and field programmable gate arrays (FPGAs) as well as algorithms and code for digital signal processing (DSP) applications.

Contact Code 564 Key Personnel

Avionics & Electrical Systems Branch (565)

The Avionics & Electrical Systems Branch provides expert leadership in the design, development, and verification of avionics systems architectures, avionics interfaces compatibility (electrical, electromagnetic, etc.), electrical harnessing, advanced data networks, and electrical ground support equipment (EGSE). The Branch provides avionics systems leads for spacecraft and payloads consisting of multiple electronics subsystems, as well as electrical systems leads, harness leads, and EGSE leads for flight instruments and spacecraft projects. The code also develops project unique electromagnetic interference/compatibility (EMI/EMC) specifications and generates the criteria and test approach to verify that EMI/EMC requirements are met.

Contact Code 565 Key Personnel

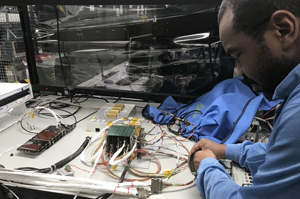

Communications Systems Branch (566)

The Communications Systems Branch mission is “to deliver leading edge telecommunication systems and technology to advance NASA missions, scientific discovery, and innovation,” and the vision of the Branch is “to enable a deeper understanding of the universe for the benefit of humankind, by providing advanced telecommunication solutions.” Code 566 maintains core communications and network engineering disciplines and facilities for the analysis, design, test, implementation, and demonstration of RF, digital and optical communication systems and networks. The Branch also provides mission design & analysis services, components and testing for the unique needs of the SmallSat/CubeSat mission community. The code provides expertise in both spaceflight and ground communications and network engineering while working closely with flight projects and mission services to develop space-to-space and space-to-ground mission operations communications.

Contact Code 566 Key Personnel

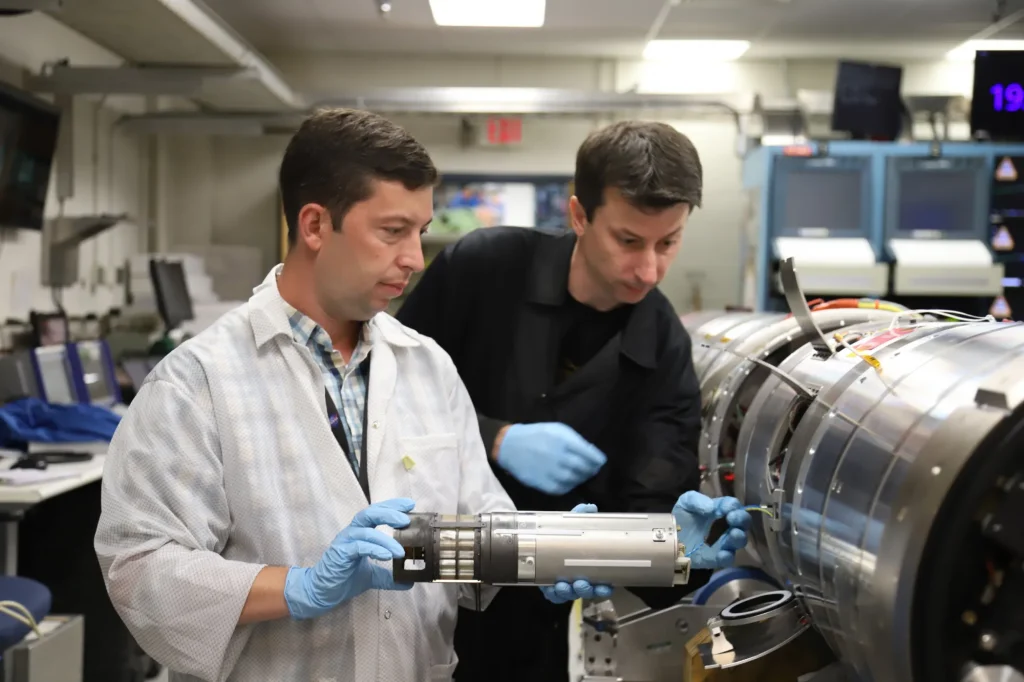

Flight Systems Integration & Test Branch (568)

The Flight Systems Integration & Test Branch is responsible for leading the integration and test activities for flight science instruments, special payloads, carriers, and spacecraft, as well as conducting functional, performance, and environment tests on these flight systems. Components and/or subsystems are received by the Branch after completion of component/subsystem level verification programs for integration into the system. The Branch develops and sustains a cadre of Integration and Test (I&T) managers to plan and coordinate I&T activities for the flight system. The Branch develops and maintains a cadre of Test Conductors (TCs) to perform tests on the various components and subsystems that are integrated to the flight system. The Branch develops and maintains a cadre of technicians to support integration and de-integration of components, as required.

Contact Code 568 Key Personnel

Wallops Electrical Engineering Branch (569)

The Wallops Electrical Engineering Branch is responsible for the conception, analysis, design, development, validation, and implementation of flight electrical/electronics, communications and tracking, and electrical ground support systems for the Wallops Flight Facility (WFF) missions, projects, and technology initiatives. Customers include suborbital and special projects, mission services, and observational science initiatives as well as other NASA programs and projects. The Branch provides electrical engineering expertise for development of flight and ground electronic instrumentation and communications & tracking for WFF expendable launch vehicles, sounding rockets, aircraft, unmanned aerial vehicles, balloons, small satellites, and special space-, air- and ocean-borne payloads. Mission services and capabilities include spectrum management, RF link budget analysis, and range instrumentation operational readiness.

Contact Code 569 Key Personnel